Preface:

Today our topic is the 7 extraction techs of fragrance and 3 derivatives.

let’s get into the 3 derivatives first.

Natural Fragrance, Synthetic Fragrance and Essential Oil

Natural Fragrance:

Natural fragrances are made up of essential oil, absolutes, extracts, CO2’s and isolates of the natural aromatic components taken from the complex scent of the essential oil. Natural fragrances are made in a laboratory but rather than being made from synthetic materials. They are created by isolating one of the natural aromatic components from a complex scent such as that of an orange or rose. These single scents are called isolates.

A natural isolate is a single chemical, isolated from a plant, that has a smell. It is a part of something real rather than man-made from another material.

Synthetic Fragrance:

Synthetic fragrances are just as you’d expect, a chemically-composed scent. Especially to a beginner or first-time fragrance buyer, a synthetic alternative may smell quite similar to its natural counterpart.

Essential Oil:

Essential oils are a highly concentrated version of the natural oils in plants. Essential oils contain a wide range of individual components and scent molecules all in one bottle of essential oil.

Steam Distillation

1.In-water distillation

put the raw materials on the sieve plate or directly into the distillation pot, add water to the pot to soak the material layer, and heat the bottom of the pot.

2.Above-water distillation

The raw materials are placed on the sieve plate. The amount of water added to the pot must meet the distillation requirements, but the water surface should not be higher than the sieve plate and ensure that the water does not splash the wet material layer when it evaporates.

3.Direct steam distillation

A circular pipe with a hole is installed under the sieve plate, and the external steam is directly sprayed through the small hole and enters the sieve hole to heat the raw material.

4.Water diffusion steam distillation

This is a novel distillation technique applied in recent years. Water vapor enters from the top of the distillation pot, and the steam gradually penetrates into the material layer from top to bottom. At the same time, the air in the material layer is pushed out. The essential oil from the water dispersion and mass transfer can enter the bottom condenser without full gasification.

The steam is diafiltration type, the distillation is uniform, consistent and complete, and the water-oil condensate enters the condenser faster, so the quality of the obtained essential oil is better and the yield is higher

Features of steam distillation:

1.simple equipment

2.easy to operate

3.low cost

4.large output

Extracts:

Essential Oil

Solvent Extraction

(liquid-solid extraction or liquid-liquid extraction)

When a specific plant is very sensitive to heat and cannot be distilled (such as jasmine, tuberose, resin, beans, dates),We use volatile organic solvents to extract the aromatic components of plant raw materials to dissolve them into organic solvents, Either hexane or diethyl ether is used to remove the aromatic lipids and waxes from the plant matter. Then a vacuum is used to remove the chemical solvents, which are recycled for re-use. The aromatic plant waxes and lipids remain as a solid waxy “concrete.

Concretes are extremely fragrant but they are solid at room temperature and difficult to use. When ethyl alcohol is used to further extract exclusively the low-molecular-weight fragrance material from the concrete, the result is an “absolute.” Absolutes are also extremely fragrant. They are less viscous (more liquid) at room temperature and more expensive than concretes.

Features of solvent extraction:

1. Liquid-solid extraction does not require heating, in addition to retaining volatile components, it can also extract important, non-volatile components.

2. Liquid-liquid extraction generally requires heating, but the temperature will be much lower than the distillation method.

3. The extracts are usually solid or jelly-like, easy to store and used for reprocessing.

4. The semi-finished extracts are insoluble in low-concentration ethanol. It needs to be processed again by other methods.

5. The solvent consumption is high, the equipment is expensive, and the production cost is high.

6. The final extract-absolute is extremely fragrant.

Extracts:

Concrete,Tincture,Absolute

Expression Extraction

(pressing or squeezing)

The expression is one of the methods for extracting essential oils from plant aromatic raw materials, but there are not many varieties using this method, and the application range is not as wide as the steam distillation method.

This method is mainly used for the peels of citrus fruits, such as lemon, sweet orange, bergamot and lime.

The pressing method is not subject to heat during processing, so it is also called cold pressing.

extraction-process.jpg)

Features of expression extraction:

1. Yield(extraction rate) is lower than distillation.

2. Extracts’ aroma is close to that of natural fresh orange fruit, with 99% similarity.

3. Low cost and low energy consumption

4. It has complicated operation and low oil yield, which is not suitable for industrial production

Extracts:

Essential Oil

Enfleurage Extraction

The principle of enfleurage’s production of natural fragrances is similar to the solvent method, except that the method uses non-volatile solvents or solid adsorbents.

Enfleurage extraction is fairly expensive and labor-intensive. During the enfleurage process, a layer of fat (animal fat or solid plant oil, such as coconut oil) is spread on a plate of glass. Delicate petals or flowers are placed on top of the layer of fat; they are placed as close together as possible, without touching one another. Another plate of glass is placed on top of the flower material and the process is repeated. The glass-fat-flower sandwich may have up to ten layers and must set at room temperature for three days.

After three days, the sandwich is carefully dismantled and the used flowers are removed and replaced with fresh flowers and the sandwich is re-assembled. In this manner, the fats are impregnated with the concentrated scent of the flowers.

Finally, after about a month and up to twelve changes of flower layers, the fat is scraped from the glass plates as a waxy enfleurage pomade. Manoi d’Tahiti Oil is an example of enfleurage pomade made from solid coconut oil and Tahitian Monoi flowers.

Due to the moisture content, enfleurage pomades promote and sustain bacterial growth. When ethyl alcohol is added to the enfleurage pomade to dissolve the fragrant oils and the ethyl alcohol is then evaporated off, only the essential oils remain.

(A part of content originally published in the Soap Guild Journal in June 2007)

enfleurage

enfleurage extraction in moive.

Features of enfleurage extraction:

1. It does not require heating, the aromatic components are not easily destroyed and retain the best aroma character.

2. Suitable for the extraction of aroma components of some precious flowers.

3. The disadvantage is that the adsorption volume of the adsorbent is small. When the processing capacity is large, a large amount of adsorbent is consumed, and the adsorbent needs to be regenerated, which also brings certain difficulties to the continuous and automated operation of the production process.

Extracts:

Pomade, Essential Oil

Supercritical Fluid Extraction

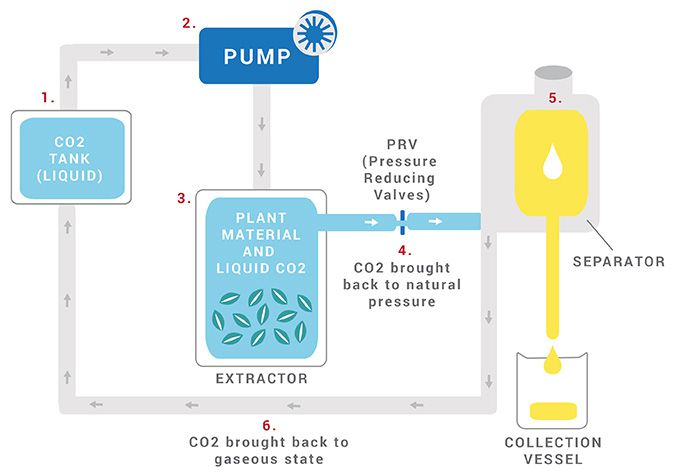

Supercritical fluid extraction is a relatively new technique that has emerged since the 1980s for extracting fragrant compounds from a raw material, which often employs supercritical CO2 as the extraction solvent. When carbon dioxide is put under high pressure at slightly above room temperature, supercritical fluid forms (Under normal pressure CO2 changes directly from a solid to a gas in a process known as sublimation.) Since CO2 in a non-polar compound has low surface tension and wets easily, it can be used to extract the typically hydrophobic aromatics from the plant material. This process is identical to one of the techniques for making decaffeinated coffee.

In supercritical fluid extraction, high-pressure carbon dioxide gas (up to 100 atm.) is used as a solvent.

Due to the low heat of process and the relatively unreactive solvent used in the extraction, the fragrant compounds derived often closely resemble the original odor of the raw material. Like solvent extraction, the CO2 extraction takes place at a low temperature, extracts a wide range of compounds, and leaves the aromatics unaltered by heat, rendering an essence more faithful to the original.

Since CO2 is gas at normal atmospheric pressure, it also leaves no trace of itself in the final product, thus allowing one to get the absolute directly without having to deal with concrete. It is a low-temperature process, and the solvents are easily removed. Extracts produced using this process are known as CO2 extracts.

Features of supercritical fluid extraction:

1. The final extracts have no residual solvent, no peculiar smell, maintains the original appearance of the top note and endnote.

2. A higher yield than that of distillation.

3. The supercritical fluid extraction method is not suitable for extracting natural flavors of fruits which contains excessive water content.

4. Require large equipment investment and high technical requirements.

Extracts:

Essential Oil

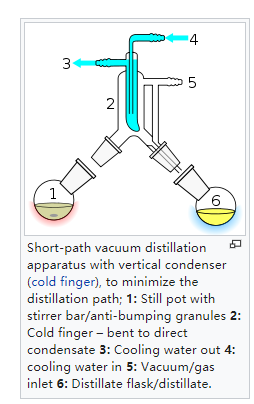

Molecular Distillation Extraction

(shot path distillation)

Molecular distillation is a new type of high-tech liquid-liquid separation or fine separation method.

Molecular distillation is different from the traditional distillation method. Its principle is the difference in the average free path of the molecular movement of different substances, so as to achieve the separation of substances, and can operate at a temperature far below the boiling point.

Molecular distillation runs under low oxygen conditions, with the short heating time of materials, and low operating pressure (high vacuum).the high degree of separation and yield, good product quality. The composition of natural substances during the distillation will not be polluted by oxygen and solvent.

So the aroma and purity of the extracts are extremely excellent.

Especially suitable for the separation and purification of high boiling point, heat sensitivity, and easy oxide materials. This technology has been widely used in the fields of petrochemicals and food spices and is particularly suitable for the extraction and separation of natural substances.

Features of molecular distillation:

1. Molecular distillation technology can separate substances that are difficult to separate by traditional distillation.

2. It has a high degree of vacuum, usually, molecular distillation is operated at very low pressure, so the material is not easy to be damaged by oxidation.

3. The purity of the extracts is extremely high.

4. Low operating temperature and short distillation time, suit for heat-sensitive raw materials.

5. Expensive equipment.

Extracts:

Essential Oil

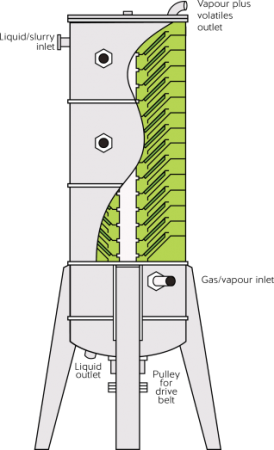

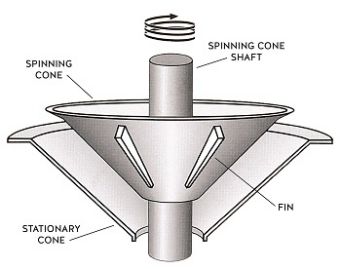

Spinning Cone Column (SCC)

Spinning Cone Column (SCC) is a new form of distillation technique, especially in the field of preparative separation of flavor substances.

The core of the rotating cone column separation device is the SCC separation column, which is regarded as a distillation or stripping column. It belongs to a kind of mass transfer devices such as a packed column, plate column, and bubble column.

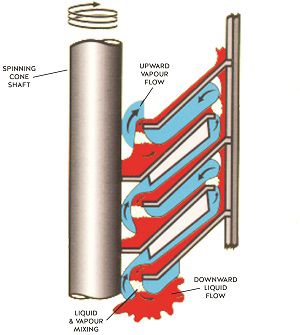

The main part is an upright stainless steel cylinder with a rotating shaft in the center, which is formed by stacking alternating rotating cones and fixed cones. The rotating cones are connected to the shaft, and the fixed cones are installed on the inner wall of the cylinder.

When working, the materials fall down layer by layer along the surface of the cone, and the steam extracts and separates the aroma and soluble substances from the liquid or pulpy substances under vacuum.

The biggest feature of SCC is that due to the rotation of the conical disc, the centrifugal effect can spread the product into a film so that the steam can completely extract the volatile substances in the raw materials. At the same time, due to the sufficient contact between the steam and the thin film, sufficient heat and mass transfer are carried out with each other, and the soluble substances can be completely extracted and dissolved in the solvent. In this way, both volatile substances and soluble substances can be extracted.

pictures from flavourtech.com

Features of SCC:

1. The extracted volatile substances are the most complete with the highest yield

2. The viscosity of the raw material can be very high, up to 20,000cps

3. Low energy consumption

4. Short distillation time (less than 20s)

5. Wide temperature control range (30-120 degrees Celsius)

Extracts:

Essential Oil

These advantages enable it to maintain natural flavor when processing heat-sensitive raw materials, which are the main reasons why SCC has received widespread attention.

Currently, SCC is used in more than 20 countries and has a wide range of applications. The world-renowned flavor and fragrance companies all use the equipment corresponding to this method to produce natural fragrance.